复杂原始模型开模

概述

Overview

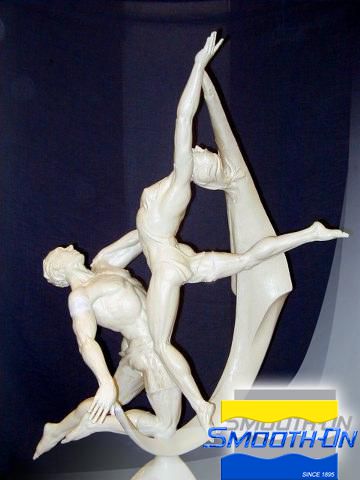

Ever wonder how to make a mold of a complex original? Sculptor Bill Kilpatrick’s exquisite creation entitled "Celebration" posed just such a molding challenge. Sculpted from Chavant® modeling clay, the piece had delicate detail, complex angles and severe undercuts that would test even the most experienced mold maker. Tim Maslyn, of Tim Maslyn Studios, had a simple answer, "break it down and make multiple molds and castings."

The goal was to reproduce the detail of the piece exactly. Mr. Kilpatrick needed multiple castings for upcoming exhibitions, and the finished castings had to be inexpensive and lightweight. Conventional molding and casting methods did not lend themselves to this application.

Each porcelain-like reproduction made was identical to the original clay sculpture. An assembled finished casting weighs less than 40 lbs. and can easily be carried by one person. The original weighed over 300 lbs.

Materials Used in this Tutorial

- Sulfur-Free Modeling Clay

- Brush-On 40

- Plasti-Paste

- Smooth-Cast 320

- Foam-iT 5

- Mixing Sticks

- Mixing Containers

Bill Kirkpatrick touches up his original clay sculpture, while Tim Maslyn helps cut the clay model into sections. Maslyn then clays up the female model for molding. The clay shim provides a flange to support the first half of the mold until the rubber and support shell are cured. Channels are carved into the clay to form a tight fit for rubber mold halves. The female portion of the sculpture has been shimmed so two rubber mold halves will fit together.

Step 2: Applying Brush‑On 40 and Plasti‑Paste

Brush-On® 40 rubber is applied to the piece in four separate layers. Alternate layers of rubber are tinted to assure thorough coverage. Once all of the rubber layers are cured Plasti-Paste® is applied to form a strong, light support shell. When the mold is removed from clay, it reveals that it has captured perfect detail

Step 3: Casting

Smooth-Cast® 320 liquid plastic is painted onto the surface of the mold. The mold halves are strapped together for rotational casting of the plastic. More resin is poured into the mold to strengthen the seam. The rubber mold has recreated every detail of the original. The female model is reproduced as a hollow casting identical to the original.

Step 4: Finishing

Foam-iT!® 5 is poured into the casting to provide structural strength. Plastic castings are assembled to create a perfect reproduction. The finished casting reflects perfect proportion and detail.

文件下载 ›