使用Equinox修复古董相框

概述

Overview

Equinox™ Silicone Putty products are new silicone compounds (platinum catalyst) that can be easily mixed and applied by hand to a variety of surfaces. Equinox Putty is mixed in equal amounts (1A:1B) by volume. Pot life is about 1 minute with a cure time of about 7 minutes at room temperature (72°F/ 23°C). Equinox™ 40 is a slower version with a 30-minute pot life and 5-hour demold time.

Equinox™ Silicone Putty is convenient, no mess – fastest, easiest way yet to make a mold.

In this example, Equinox™ is used to mold a section of an antique wooden picture frame. A casting is poured into the mold, which is then finished and glued in place to form a perfect repair.

Materials Used in this Tutorial

- Equinox 40

- Smooth-Cast 325

- Metal Powders

- Syringe

- Mixing Sticks

- Mixing Containers

- Glue

- Shoe Polish

- Acrylic Spray

- Step 1: Mixing and Applying Equinox™

Dispense equal amounts of putty in your hand. Fold part A around part B until a uniform color is achieved, then press the putty firmly into similar frame detail. Demold the silicone putty from the frame in 5 hours.

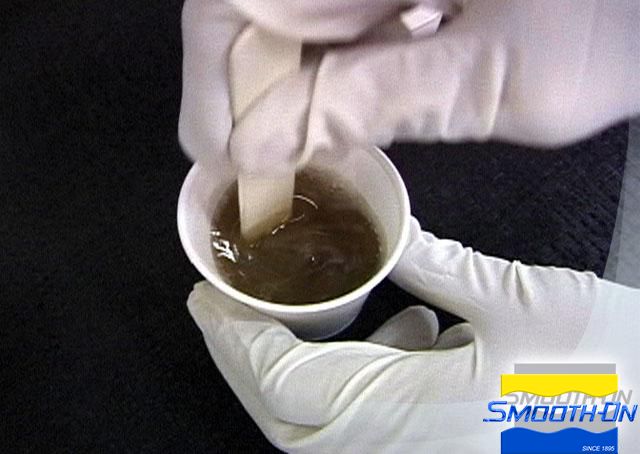

Step 2: Measure Smooth-Cast™ 325

Measure Smooth-Cast&™ 325 resin and metal powders, then mix resin and metal powders together.

Step 3: Casting Smooth-Cast™ 325

Fill the syringe with the resin mixture, then dispense the resin into the mold rubber. Demold the casting to reveal the exact detail.

Step 4: Finishing Restoration

Highlight the resin with shoe polish and seal it with clear acrylic spray, then glue the casting into place.

You now have a perfect restoration!

文件下载 ›