Crystal Clear® 200

小心:不适用于家庭使用。此产品仅供工业使用。适当的通风,佩戴需要NIOSH认可的呼吸器和防护服(手套和长袖),将吸入和皮肤过敏的风险降至最低。如果呼吸受到影响或出现皮疹,请立即停止使用本产品并寻求医疗救助。使用前请阅读SDS。

说明

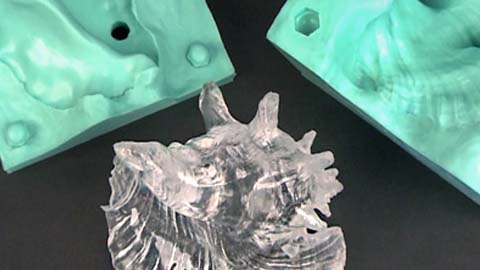

Selecting A Mold Rubber - Pour into a urethane rubber mold (Vytaflex urethane – release agent required), tin cured silicone mold (Mold Max™ silicone) or Mold Star™ 15, 16 or 30 (not Mold Star™ 20T) platinum cured silicone. Do not use other rubber mold products.

If using Mold Max silicone; to prevent cure inhibition, post-cure newly cured silicone mold for 8 hours at 60° C / 150° F and let cool prior to casting resin. If you are unsure about surface compatibility, a small scale trial casting should be made.

For Best Results Before Pouring Crystal Clear™ Into Mold: Pre-heat rubber mold at 212°F / 100°C for 4 hours. This will minimize chances of fish-eyeing, suck back, corner rounding, large bubbles, etc. in finished casting.

IMPORTANT: Shelf life of product is reduced after opening. Remaining product should be used as soon as possible. Immediately replacing the lids on both containers after dispensing product will help prolong the shelf life of the unused product. XTEND-IT™ Dry Gas Blanket (available from Smooth-On) will significantly prolong the shelf life of unused liquid urethane products.

MEASURING & MIXING - Liquid urethanes are moisture sensitive and will absorb atmospheric moisture. Mixing tools and containers should be clean and made of metal or plastic. Materials should be stored and used in a warm environment (73°F/23°C).

Measuring - Materials should be stored and used at room temperature (73°F / 23°C). The proper mixing ratio is 100A: 90B by weight. You must use an accurate scale (gram scale or triple beam balance scale) to weigh these components properly Dispense the required amount of Part A into a mixing container. Weigh out the appropriate amount of Part B and combine with Part A.

Mixing - Mix SLOWLY, but thoroughly, for at least 90 seconds making sure that you scrape the sides and bottom of your container several times. If coloring or filling Crystal Clear™ product, add filler or pigment dispersion to Part B and mix thoroughly before adding Part A.

Bubbles in the finished casting will be greatly reduced by vacuum degassing prior to pouring. Subject mixture to 29 h.i.g. mercury in a suitable vacuum chamber until mixture rises, breaks and falls. Allow for 3 to 4 times volume expansion in mixing container.

Pouring - If casting Crystal Clear™ into a rubber mold, pour mixture in a single spot at the lowest point of the mold. If encapsulating an object, do not pour the mixture directly over the object. Let the mixture seek its level. A uniform flow will help minimize entrapped air.

For Best Results: Bubble elimination is best achieved by pressure casting. After pouring the mixed compound, the entire casting assembly (mold, dam structure, etc.) is placed in a pressure chamber and subjected to 60 PSI (4.2 kg/cm2) air pressure for at least two hours prior to heat curing.

Post Curing - Castings will achieve maximum physical properties, better heat and UV resistance if Crystal Clear™ is post cured. Post curing is recommended if castings are thin or of low mass concentration. Castings should be post cured in a mold or support structure. Post Cure Schedule: Allow the material to cure for 6–8 hours at room temperature followed by 6 hours at 150°F–160°F (65°C–72°C). Allow casting or part to cool to room temperature before demolding. Materials should be stored and used in a warm environment (73°F / 23°C). Castings will reach ultimate physical properties at room temperature in 5–7 days. Castings removed from mold before recommended cure may exhibit a tacky surface that can be eliminated by exposing casting to 150°F / 65°C for 6 hours.

Casting Thickness & Cure Time - The cure time and ultimate shrinkage of all Crystal Clear™ products will vary depending on mass concentration, thickness of the casting, mold configuration, etc. For example, a 200 gram mass of CC 200 will cure faster if left to cure in a conical vessel (cup) versus a casting dispersed as a thin sheet measuring 3 centimeters square by 1 mm thick. This is due to the heat generated by the concentration of material in the cup versus heat that is dissipated from the sheet casting. Castings will resist yellowing when exposed to UV, but may darken over time.

Crystal Clear™ 200 is intended for a casting thickness ranging from ½” to 3” at a casting weight maximum of 16 lbs. (7.25 kgs.) Castings greater than 3” should be layer cast.

Because no two applications are quite the same, a small test application to determine suitability for your project is recommended if performance of this material is in question.