EpoxAmite® 101

EpoxAmite®101无填充、低粘度低、无味、室温固化。固化后的环氧树脂具有出色的物理和应用性能。产品可以打磨、成型、机械加工、钻孔、攻丝和涂漆。

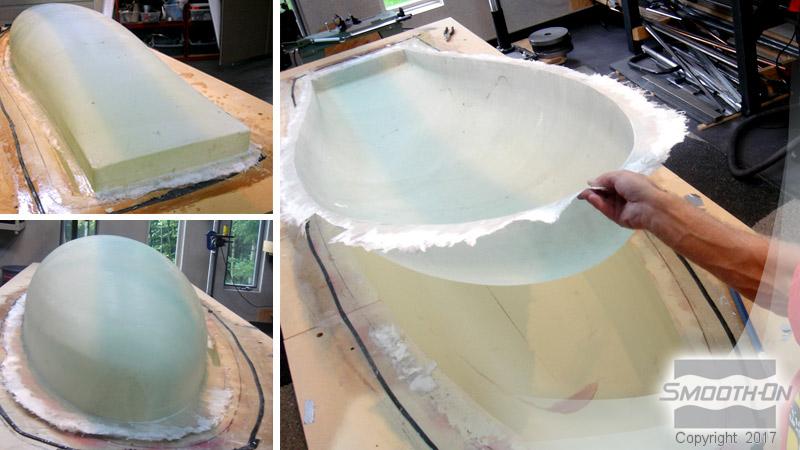

EpoxAmite®101可用于增强材料,如S-Glass、E-Glass,芳纶和碳纤维增强,用于层压应用或复合部件。EpoxAmite®101也可与填充剂(如气相二氧化硅)混合,用于胶衣涂层应用。可以添加Urefil®3、Urefil®7和其他填料用于整流、切片或粘合应用场合。

说明

Materials should be stored and used in a room temperature environment (73°F/23°C). Elevated temperatures will reduce Pot Life. EpoxAmite® 100 Resin 101 Hardener must be properly measured and thoroughly mixed to achieve full, high-strength, solid-cure properties.

Applying A Release Agent – For releasing epoxy from non-porous surfaces such as resin, metal, glass etc., use Ease Release 200 or 205 (available from Smooth-On) to prevent adhesion.

Measuring / Dispensing – Accurate ratio measurements by volume or weight are required for the material to cure properly and develop full physical properties. Refer to specified Mix Ratios in Handling Properties for proper measurements. Dispense Parts A and B proper proportions into clean plastic, metal or wax-free paper containers.

Adding Color - EpoxAmite® 101 can be colored with SO Strong® or UVO® colorants. Pre-mix tint with Part A thoroughly and then add Part B.

Mixing – Be sure mixing utensils are clean and free of any potential contaminants such as dirt, dust or grease. Mix Parts A and B thoroughly for at least 3 minutes with a square edged mixing stick. Be aggressive and scrape sides and bottom of mixing container several times. Use the square edge of mixing stick to bring material off of the sides of container and blend. If using a drill mixer, follow with hand mixing as directed above to ensure thorough mixing. NOTE: If mixture is to be used for coating, pour into a roller pan to extend Pot Life.

Adding Fillers - A variety of dry fillers can be added. Pre-mix dry filler with Part A before adding Part B.

Important - Mixed EpoxAmite® 100 Resin with EpoxAmite® 101 Hardener is exothermic, meaning it generates heat. A concentrated mass of mixed epoxy in a confined area such as a mixing container can generate enough heat to melt a plastic cup, burn skin or ignite combustible materials if left to stand for its full Pot Life. Do not use foam or glass mixing containers or pour sections thicker than 1/8” (0.32 cm). If a batch of mixed epoxy begins to exotherm, move it to an open air environment.

Applying – Mixed EpoxAmite® 101 is initially a low viscosity liquid that can be poured up to 1/8” (0.32 cm) thickness.

Laminating: cut the bristles of a chip brush 30% for better control. After epoxy is mixed, you must work quickly to apply multiple layers. Brush an initial gel coat of epoxy over surface. Apply reinforcement fabric evenly into gel coat. Using brush, gently use stippling motion to work fabric into epoxy. Ensure fabric ply is saturated. Plastic polyethylene spreaders may also be used.

Alternate additional thin layers of epoxy and fabric using above application method. Add additional epoxy as needed to wet out subsequent layers. Repeat as necessary until desired thickness is attained. After final layer of fabric is applied, use lamination roller to evenly distribute epoxy and reduce air bubbles. Be mindful of your Thin Film Working Time.

Cure Time: Refer to specified Cure Times in Handling Properties at room temperature depending on mass. Cured material will be hard and unable to penetrate with a finger nail. Cured epoxy can now be dry sanded. If machining or sanding, wear NIOSH approved mask to prevent inhalation of particles.

Heat Curing - This product will cure at room temperature and does not require heat. Cure time can be reduced by applying mild heat. The higher the curing temperature is, the higher the resulting Heat Deflection Temperature. With a higher temperature cure, a service temperature of 138°F / 59°C can be attained. Allow epoxy to cure for 30 minutes and then cure for 1 hour at 200°F / 93°C. Allow casting to cool to room temperature before handling.

Painting – Cured EpoxAmite® 101 can be painted and / or primed and then painted with acrylic enamel paints. Let paint fully dry before putting part into service.

Removing Epoxy – Uncured / Non-curing epoxy: Scrape as much material as possible from the surface using a scraper. Clean the residue with E-POX-EE KLEENER® available from Smooth-On, lacquer thinner, acetone or alcohol. Follow safety warnings pertaining to solvents and provide adequate ventilation.

Because no two applications are quite the same, a small test application to determine suitability for your project is recommended if performance of this material is in question.