EZ-Mix® 40

说明

Some Materials Must Be Sealed - Urethanes are adhesive. To prevent adhesion between the rubber and model surface, models made of porous materials (gypsum plasters, concrete, wood, stone, etc.) must be sealed prior to applying a release agent. SuperSeal® (available from Smooth-On) or One Step® are fast drying sealers suitable for sealing porous surfaces without interfering with surface detail. Sonite Wax®or high-grade shellac is suitable for rough contours. A high quality Shellac is suitable for sealing modeling clays that contain sulfur or moisture (water based). Thermoplastics (polystyrene) must also be sealed with shellac or PVA. In all cases, the sealing agent should be applied and allowed to completely dry prior to applying a release agent.

Non-Porous Surfaces - Metal, glass, hard plastics, sulfur free non-drying clays, etc. require only a release agent.

Applying A Release Agent - A release agent is necessary to facilitate demolding when casting into or over most surfaces. Use a release agent made specifically for mold making (Universal® Mold Release available from Smooth-On). A liberal coat of release agent should be applied onto all surfaces that will contact the rubber.

IMPORTANT: To ensure thorough coverage, lightly brush the release agent with a soft brush over all surfaces of the model. Follow with a light mist coating and let the release agent dry for 30 minutes.

Because no two applications are quite the same, a small test application to determine suitability for your project is recommended if performance of this material is in question.

Liquid urethanes are moisture sensitive and will absorb atmospheric moisture. Mixing tools and containers should be clean and made of metal or plastic. Materials should be stored and used in a warm environment (73°F / 23°C).

Mixing - After dispensing equal amounts of Parts A and B into mixing container, mix thoroughly for 3 minutes making sure that you scrape the sides and bottom of the mixing container several times. Pour all contents into new, clean mixing container and mix for 2 minutes.

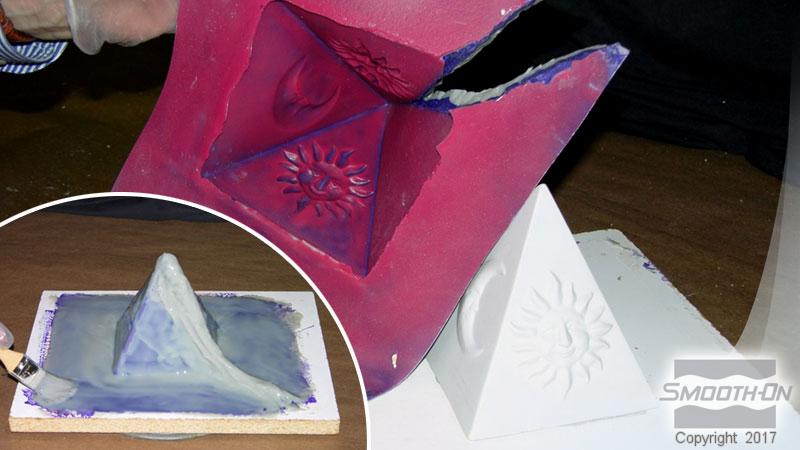

Applying The Rubber - This product must be applied in layers. Mold makers generally find that four layers (minimum 3/8”) thickness is suitable for a working mold. Using a stiff brush, the first coat of rubber should be applied in a thin layer to capture intricate detail. Use dabbing strokes, especially around undercuts, to reduce entrapped air. Subsequent coats will add strength to the mold. Let the first coat dry for 60 minutes at room temperature until it becomes “tacky” before adding the next coat. Repeat until the necessary thickness is achieved. Do not allow rubber to fully cure between layers, as delaminating may result. Note: Although not necessary, adding a small amount of SO-Strong® liquid color pigment to every other mix of rubber will help you distinguish one layer from the next. This will ensure that you apply a thorough coating each time and help build uniform layers.

IMPORTANT: Shelf life of product is reduced after opening. Remaining product should be used as soon as possible. Immediately replacing the lids on both containers after dispensing product will help prolong the shelf life of the unused product. XTEND-IT® Dry Gas Blanket (available from Smooth-On) will significantly prolong the shelf life of unused liquid urethane products.

Curing - Allow the mold to cure overnight (at least 16 hours) at room temperature (73°F / 23°C). Do not cure rubber where temperature is less than 65°F / 18°C. Post curing the rubber after rubber has cured at room temp. (applying heat – 150°F / 60°C for 4 – 6 hours) will increase physical properties and performance significantly.

Post Curing - Post curing the rubber after rubber has cured at room temp. (applying heat—150°F / 60°C for 4–6 hours) will increase physical properties and performance significantly.

Apply A Support Shell - Once the mold is fully cured, a rigid support shell (mother mold) is needed to support the rubber mold during casting. Plasti-Paste® II is a trowelable plastic which is ideal as a mother mold material.

Using The Mold - If using as a mold material, a release agent should be applied to the mold before each casting. The type of release agent to use depends on the material being cast. The proper release agent for wax, liquid rubber or thermosetting materials (i.e. Smooth-On liquid plastics) is a spray release made specifically for mold making (available from Smooth-On or your distributor). Prior to casting gypsum plaster materials, sponge the mold with a soap solution for better plaster flow and easy release. In & Out® II Water Based Release Concentrate (available from SmoothOn) is recommended for releasing abrasive materials like concrete.

Performance & Storage - Fully cured molds are tough, durable and will perform if properly used and stored. The physical life of the mold depends on how you use it (materials cast, frequency, etc.). Before storing, the mold should be cleaned with a soap solution and wiped fully dry. Two part (or more) molds should be assembled. Molds should be stored on a level surface in a cool, dry environment. Do not stack molds, expose them to moisture or UV light.