EZ-Spray® Styrocoat®

说明

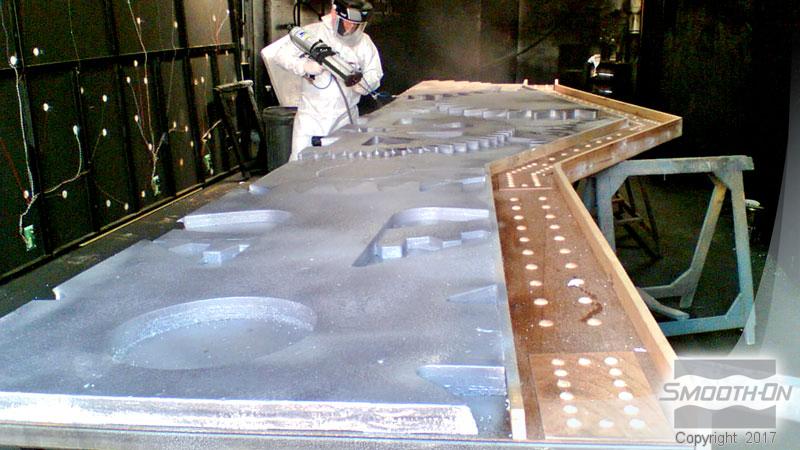

Breathing protection: Everyone in the spray area should wear an independent air supplied hood or NIOSH approved breathing mask.

Do Not Attempt To Spray Rubber Or Plastic Without First Reading The EZ~Spray® Junior Manual!

Applying A Release Agent - A release agent is necessary to facilitate demolding when spraying into a rubber mold to create castings. Use a release agent made specifically for mold making (Universal® Mold Release) available from Smooth-On or your SmoothOn distributor). A liberal coat of release agent should be applied onto all surfaces that will contact the plastic.

IMPORTANT: To ensure thorough coverage, lightly brush the release agent with a soft brush over all surfaces. Follow with a light mist coating and let the release agent dry for 30 minutes.

Because no two applications are quite the same, a small test application to determine suitability for your project is recommended if performance of this material is in question.

Remember, StyroCoat® Plastic sets up immediately.

After material cartridge is loaded & prepared depress trigger and begin spraying.

Spraying - Spray on a thin first coat, moving quickly. Spray undercuts and recesses first. Wait two minutes between first and second coats. Heat from the first coat will speed the cure of the others. Spray bottom edges with many thin coats to avoid drips and voids. Work from bottom to top. Increase the pressure for heavier coats. Consult EZ~Spray® Jr. Instruction Manual & Video for more tips on being successful with this system.

IMPORTANT: Shelf life of product is reduced after opening. Remaining product should be used as soon as possible. Immediately replacing the lids on both containers after dispensing product will help prolong the shelf life of the unused product. XTEND-IT® Dry Gas Blanket (available from Smooth-On) will significantly prolong the shelf life of unused liquid product.

Rate of Coverage - Each cartridge of StyroCoat® contains 3.75 lbs. / 1.7 kgs.. of material. Assuming a thickness of 0.1 inches (0.25 cm), one cartridge of StyroCoat® will cover approximately 6.43 sq. ft. (0.6 square meters).

Curing - StyroCoat® Plastic will harden immediately and can be handled in about one hour depending on mass and configuration.

Performance - Cured plastic is rigid and durable. It resists moisture, moderate heat, solvents, dilute acids and can be sanded, machined; primed/painted or bonded to other surfaces (any release agent must be removed). If sanding or machining, wear dust mask or other apparatus to prevent inhalation of residual particles. Plastic can be displayed outdoors after priming and painting. Unpainted castings will yellow when exposed to ultra-violet light.