Free Form® AIR

Free Form™AIR为重量极轻的环氧腻子,适用于各种工业和艺术相关的应用场合。产品为低气味、低收缩的腻子,具有独特、便宜的特点且易于使用。 Free Form™AIR按1A:1B体积混合比手混合使用。具有长时间的工作时间,并在室温下过夜固化成坚硬,刚性的环氧树脂,非常坚固。固化的FreeForm™AIR非常轻,可以漂浮在水中。可以打磨、成型和钻孔。它会随时用任何油漆上色。FreeForm也可以使用SO Strong或Ignite颜色调色。

特征

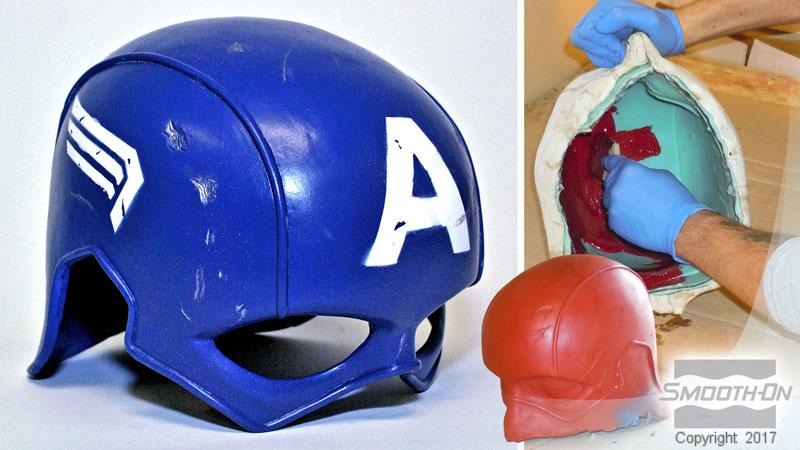

混合后,可将FreeForm™AIR压入模具中,制成轻质、细致的浇注件。可以附着在垂直表面,几乎可以应用于任何表面,包括用于粗糙雕刻的聚苯乙烯泡沫。Free

Form™AIR腻子也可用于制作刚性支撑壳或母模。

环氧树脂层压: 层压Free Form™AIR油灰在EpoxAmite™层压环氧树脂和玻璃纤维布层、碳或其他纤维之间,制作轻质复合材料部件。不需要用液体环氧树脂进行多层层压;节省时间和人力。环氧工具应用 - 用作切片材料。也适用于夹具和装置结构。

作为轻质粘合剂使用,Free Form™AIR可以与其自身和各种表面粘合,包括木头、石材和EpoxAcast Red 表面涂层环氧树脂。Free Form™AIR甚至可以在水下固化。

操作时间/工作时间:材料对质量敏感。一次混合的材料越多,使用操作时间就越少。工作提示;如果大量混合,用擀面杖压扁腻子,以减少质量浓度,延长操作时间。

厚度; 1.5英寸(3.81厘米) - 操作时间30分钟,处理时间2.5小时,24小时内完全固化。

厚度; 3/8英寸(0.95厘米) -操作时间60分钟,处理时间4小时,24小时内完全固化。

厚度; 1/8“(0.32cm) - 操作时间120分钟; 处理时间8小时,24小时内完全固化。

说明

Safety – Use in a well-ventilated area (“room size” ventilation). Generally, if you use any epoxy system on a regular basis, wearing a NIOSH approved respirator is advised. Wear safety glasses, long sleeves and rubber gloves to minimize skin contact. Wear nitrile or vinyl gloves only.

Preparation – Materials should be stored and used at room temperature (73° F / 23° C). This product has a limited shelf life and should be used as soon as possible. Mixing should be done in a well-ventilated area. Wear safety glasses, long sleeves and rubber gloves to minimize contamination risk. If making a 2 or more piece mother mold, apply appropriate shim apparatus to rubber mold exterior.

Because no two applications are quite the same, a small test application to determine suitability for your project is recommended if performance of this material is in question.

Applying A Release Agent – For releasing epoxy from non-porous surfaces such as resin, metal, glass etc., use Ease Release 200 or 205 (available from Smooth-On) to prevent adhesion.

This product is mixed by hand. You must wear gloves when mixing this material, wearing vinyl gloves reduces inhibition risk.

MIXING & MEASURING - Free Form™AIR putty comes as two parts. Dispense equal amounts (golf ball size, for example) of Part A and Part B. These products have a limited shelf life and should be used as soon as possible.

Mixing - Knead parts together aggressively to a uniform color and apply quickly to surface of tool or mold.

Applying – Mixed Free Form™AIR is a dough that can be applied up to 1.5” (3.81 cm) thickness. Mix only enough Free Form to be used at one time. Free Form™AIRwill bond to itself.

Laminating - Free Form™AIR can be used in conjunction with EpoxAcoat™ surface coat and EpoxAmite™ laminating resin to create a strong and lightweight composite tool or mold.

Use as a Sculpting Medium - Free Form™AIR can be applied to wire mesh armatures to create rigid forms for sculpting. Wire mesh for sculpting is available at most art supply stores. Free Form™AIR can be applied to polystyrene foam to create a hard, rough-sculptable and sandable surface. When applying to polystyrene foam, maximum thickness is 3/4” (1.90 cm).

Smoothing Surface – Epoxy surface can be smoothed with water or isopropyl alcohol.

Painting – Cured Free Form™AIR can be painted and / or primed and then painted with acrylic enamel paints. Let paint fully dry before putting part into service.

Cure Time - Refer to specified Cure Times in the Product Overview section at room temperature depending on mass. Cured material will be hard and unable to penetrate with a finger nail. Cured epoxy can now be dry sanded. If machining or sanding, wear NIOSH approved mask to prevent inhalation of particles. Pot Life and Cure Time values are dependent on mass and mold configuration, as epoxies are mass-sensitive.

Heat Resistance – Fully cured putty with a minimum thickness of ½” (1.27 cm) will resist temperatures up to 140°F/60°C.

Removing Uncured Free Form™AIR Epoxy Putty - Remove as much uncured material from the surface as possible. Clean any residue with soap and water. Optional - Use E-POX-EE KLEENER™ available from Smooth-On.