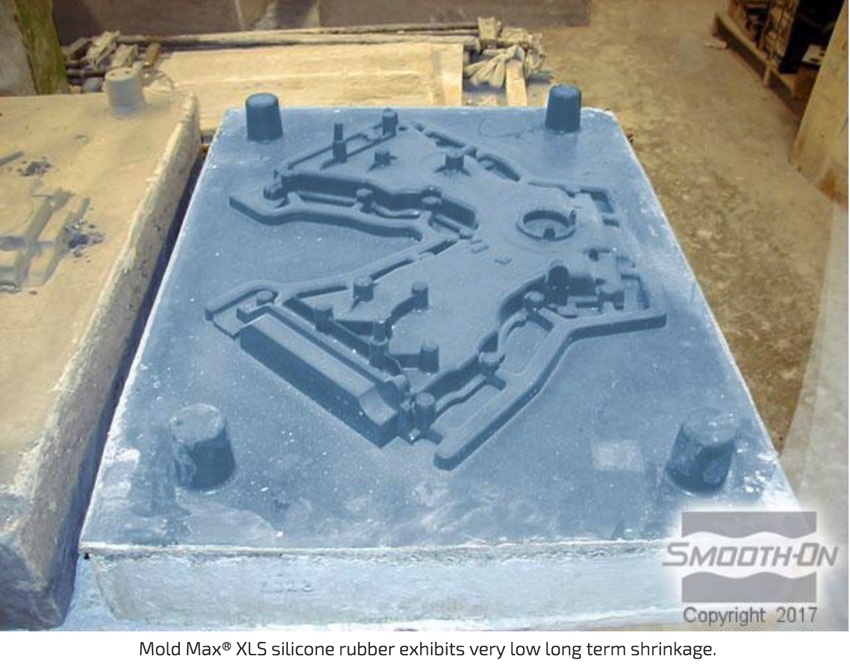

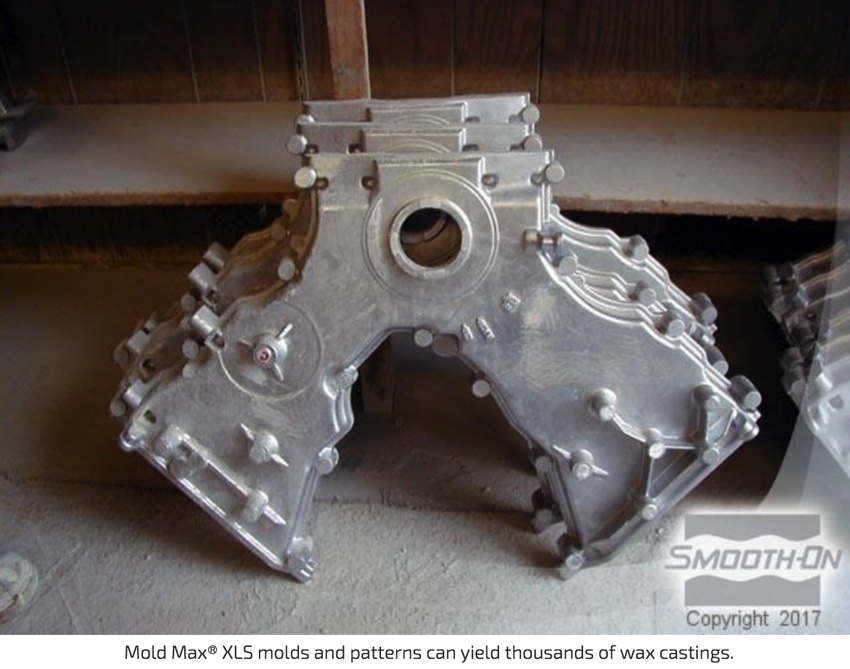

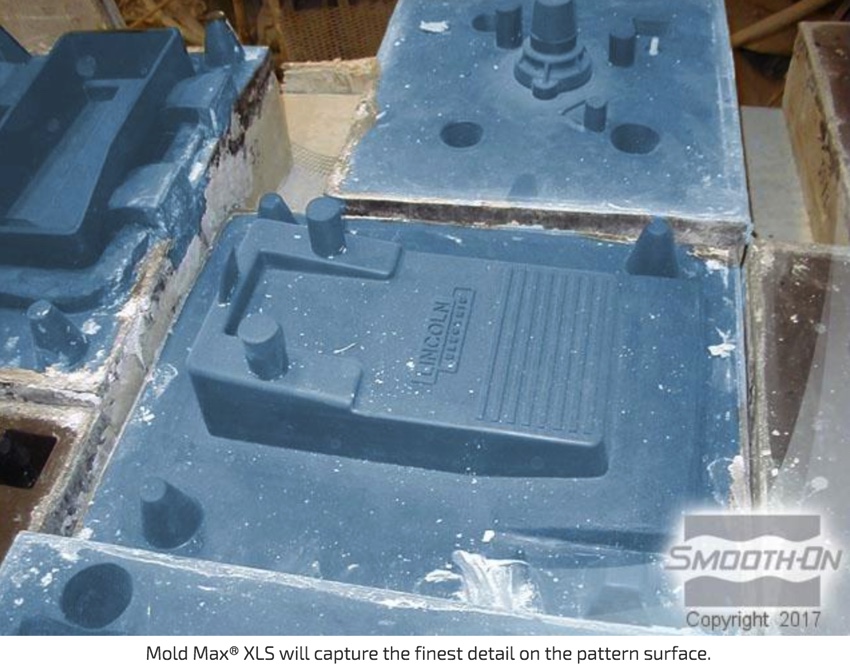

In the process of sand casting, a pattern is a replica of the original object to be cast. This pattern is used to make a negative cavity into which molten metal is poured during the casting process. Patterns typically used in sand casting include wood, metal, plastics and urethane or silicone rubber. Furthermore, patterns are made to exact standards. Materials used to make these patterns must last a reasonable amount of time and repeatedly provide dimensional stability in order to turn out acceptable castings.

This was the criteria Mr. Jose Silvaggio from Garden State Castings presented to us at Smooth-On when he called looking for a rubber that is dimensionally stable.

"I have used many rubber products for our patterns," says Mr. Silvaggio, "When I found a rubber that I was happy with, we used it for about two years then the manufacturer stopped making it without notice. I was at a loss and did not know which rubber to try next." He continues, "At around the same time, I sent one of our mold makers to Smooth-On's Moldmaking Seminar. Two days later he came back and told me about a new silicone Smooth-On had called Mold Max™ XLS, which was supposed to have good mold life and minimal shrinkage."

And Mold Max XLS Was Put to the Test

Mr. Silvaggio decided to try Mold Max XLS:

"I had a signed contract for a project, so I ordered a 5-gallon kit, made our patterns and they came out fine. We made our Cope and Drag molds, completed the job and put the patterns on the shelf. Eight months later the client called and needed the same part. By that time we had been using Mold Max XLS for other projects, but this was the first one where we returned to an old project where XLS was used. We retrieved the pattern from our mold inventory, cleaned it off and looked for separation from the mold and support jacket. If shrinkage occured, we will see it first between the rubber mold and the support jacket. There were no signs of separation and the mold performed as if we made it 24 hours ago. We didn't have to make a new pattern, which saved us time and labor!"

Mold Max XLS – eXtra Low Shrinkage