Foundrymen have long sought methods of producing metal castings of intricate shapes and to very close tolerances. The most common methods used today to produce metal castings are sandcasting, lost foam or lost wax. Lost wax, a common method used for investment casting of different metals, involves enscapsulating a wax shape or pattern in ceramic. The wax is then burned or melted out leaving a cavity of the shape.

Molten metal (bronze, copper, aluminum, etc.) is then poured into the cavity of the ceramic shell and allowed to cool before the shell is removed, thereby yielding a solid metal casting. Wax, however, can sag and distort within the ceramic shell. Wax also shrinks unpredicatably which causes problems in getting a precise metal casting and means costly post production work. The lost foam process and sand casting process each have their plusses and minuses similar to the lost wax process.

Why Water?

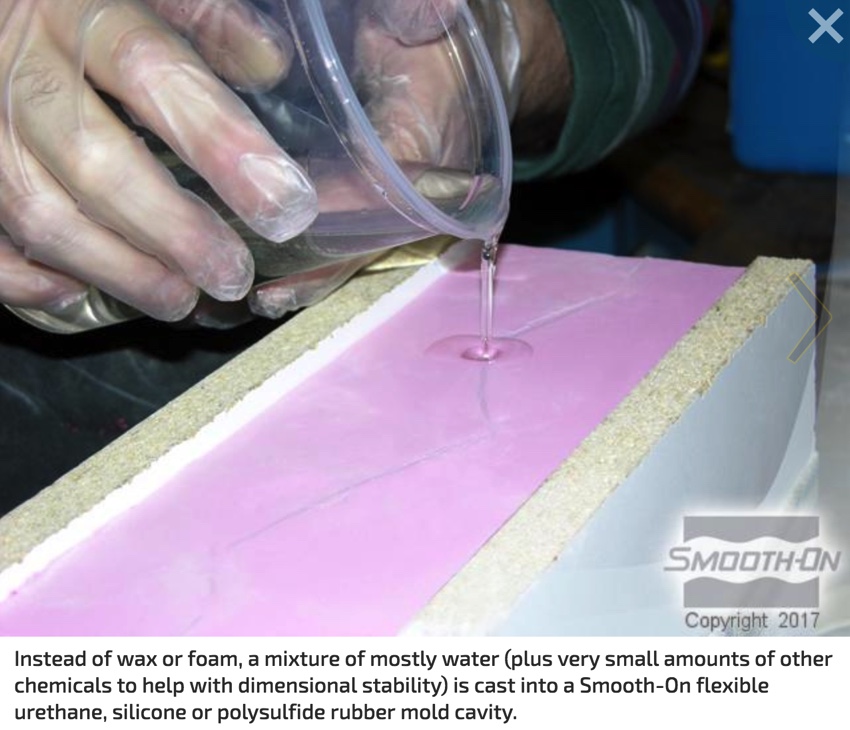

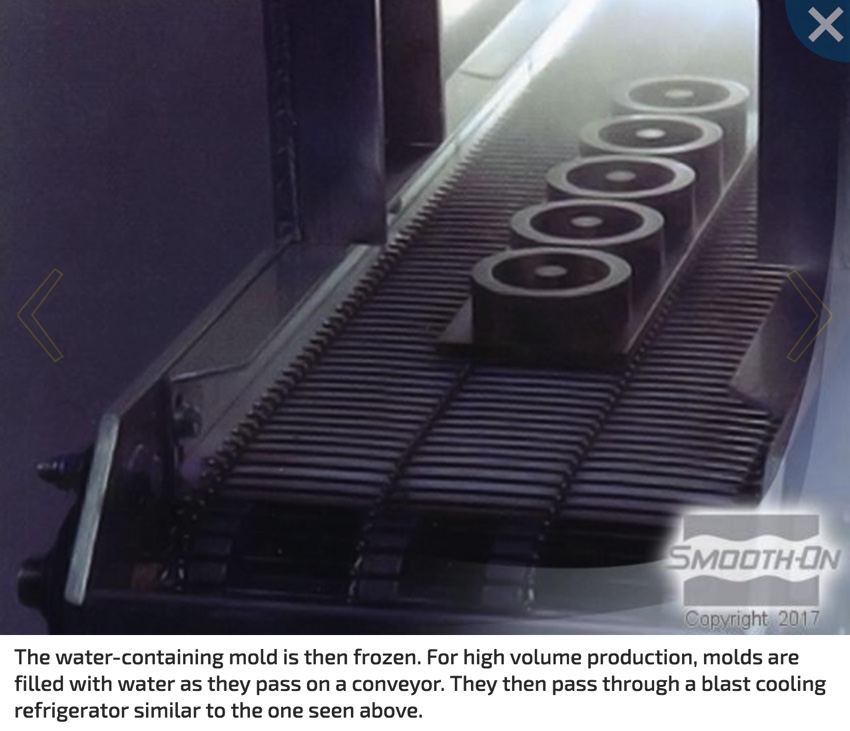

Water is dimensionally stable and very predictable as it correlates to final metal casting dimensions, thereby minimizing guess work associated with wax or foam. Accuracy of the final metal casting is improved by at least 10%. Water is also less expensive, safer to use and more environmentally friendly than wax or foam (for example, wax costs $2 - $3/lb., while water plus required additives costs $0.05 cents/lb. Using water speeds the process, saving time. Water also flows freely and does not need to be injected at high temperatures o pressure (like wax) or blown into molds (like foam). Equipment and labor costs associated with lost wax or foam processes are reduced by up to 50%.

Why Smooth-On mold rubber?

Rubber molds can be made quickly and will accomodate the expansion of water during the freezing process. Some wax or foam processes involve using metal molds, which are expensive and rigid. Rubber is cheaper and flexible. The flexibility allows for removal of ice patterns with complicated shapes and negative draft. Smooth-On rubber products are dimensionally stable and can be exposed to extreme cold temperatures with no affect. Freeze Cast Engineering exposed their Smooth-On silicone molds to -140° F / -60 ° C with no apparent shrinkage or expansion. Freezecast Engineering has a patent on the process and offers engineering and consulting services to set up a Freezecasting Operation. Their clientele list thus far includes branches of the US Military, General Motors and Ford Motor Co. The process has received endorsements from such notable organizations as The Investment Casting Institute and The Society of Automotive Engineers.

Freeze Cast Engineering Co. of Worcester, MA developed “The Freeze Cast Process” as an alternative to conventional casting methods.