Applications for Smooth-On’s Crystal Clear™ liquid plastics get larger and more varied with each passing year and include casting custom lenses for cars, creating movie glass or ice effects and making very large sculpture reproductions. Currently, there are people working on several large Crystal Clear™ casting projects around the world ranging in size from 10,000 lbs. / 4,536 kgs. to over 30,000 lbs. / 13,600 kgs. Many of these projects are beyond the scope of what these resins were originally developed for meaning that we can’t easily predict the outcome. We do our best to assist on these projects and anticipate how the material will behave when cast in large quantities, against different surfaces, encapsulating different objects, etc. While assisting on projects, we learned quite a bit and wanted to share with you one technique that can always make a significant difference in the casting outcome.

Regardless of the Crystal Clear™ product you are using, we recommend that the rubber mold (usually our Mold Max™ tin-catalyzed silicone) be heated at 212° F / 100° C for at least four hours before casting. This will minimize the chance that cured castings will exhibit undesirable casting anomalies such as fish-eyeing, suck-back, etc.

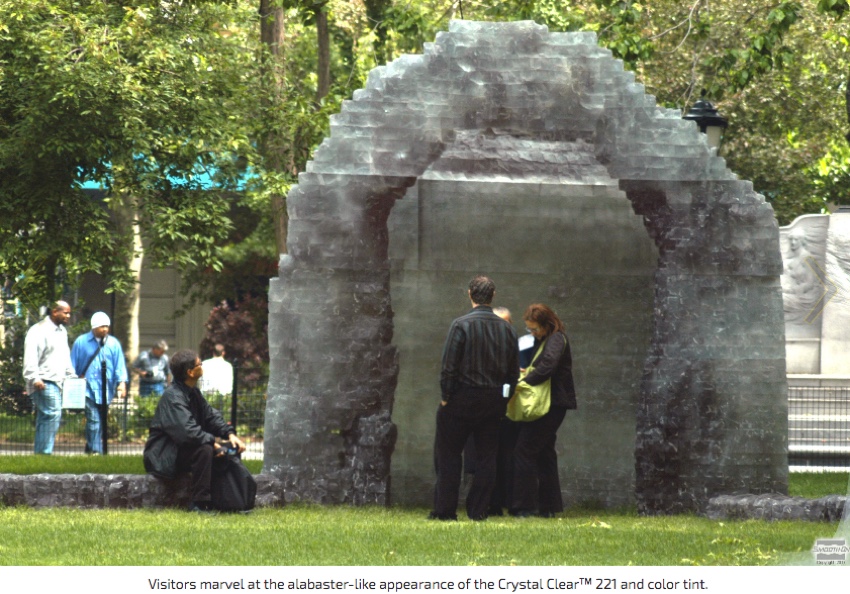

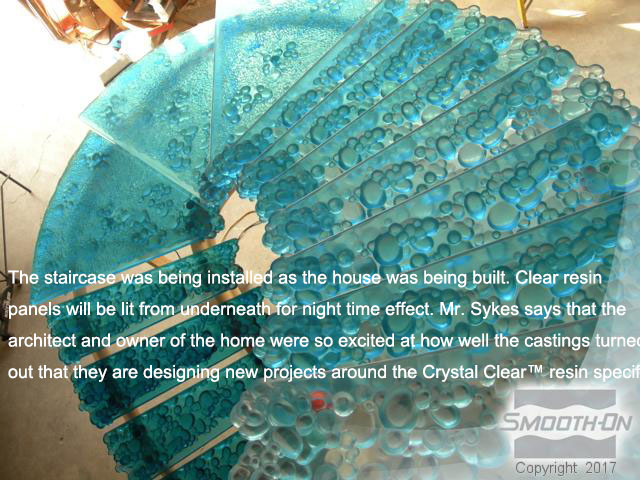

NYC Sculpture Project, Buddhist Temple Project, and Crystal Clear™ & Architecture: