TASK™ 8

特征

TASK™8具有便利的1A:1B混合比,粘度非常低,容易混合和浇注。树脂快速固化成邵氏硬度80D,并具有良好的物理性能和应用特性。为了获得最佳的耐热性,热固化该材料是必需的。有关固化时间表的详细信息,请参阅“热固化”部分。

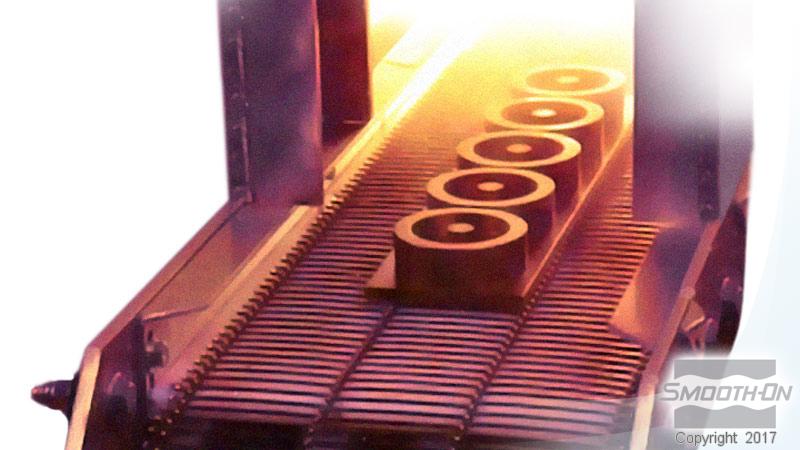

应用包括制造机器外壳,热成形和一般原型/浇注。

说明

Because no two applications are quite the same, a small test application to determine suitability for your project is recommended if performance of this material is in question.

Applying A Release Agent - A release agent is necessary to facilitate demolding when casting into or over most surfaces. Use a release agent made specifically for mold making (Universal™ Mold Release or Ease Release™ 200 available from Smooth-On or your Smooth-On distributor). A liberal coat of release agent should be applied onto all surfaces that will contact the plastic.

IMPORTANT: To ensure thorough coverage, lightly brush the release agent with a soft brush over all surfaces. Follow with a light mist coating and let the release agent dry for 30 minutes.

Most silicone rubber molds usually do not require a release agent unless casting silicone into the mold. Applying a release agent, however, will prolong the life of the mold.

MEASURING & MIXING...

Shake or stir both Part A & Part B before dispensing. After dispensing equal amounts of Parts A and B into mixing container, mix thoroughly. Stir slowly and deliberately making sure that you scrape the sides and bottom of the mixing container several times. Be careful not to splash low viscosity material out of the container.

Remember, TASK™ 8 will set up quickly. Do not delay between mixing and pouring.

IMPORTANT: Shelf life of product is reduced after opening. Remaining product should be used as soon as possible. Immediately replacing the lids on both containers after dispensing product will help prolong the shelf life of the unused product. XTEND-IT™ Dry Gas Blanket (available from Smooth-On) will significantly prolong the shelf life of unused liquid urethane products.

Pouring - Pour your mixture in a single spot at the lowest point of the containment field and let the mixture seek its level. This will help minimize air entrapment.

For Best Results . . . Best results are obtained using a pressure casting technique. After pouring the mixed compound, the entire casting assembly (mold, dam structure, etc.) is placed in a pressure chamber and subjected to 60 PSI (4.2 kg/cm2) air pressure for the full cure time of the material.

Curing - TASK™ 8 will cure in 10-15 minutes depending on mass and mold configuration. Non-hazardous fumes, which may be visible as this product starts to “gel” and cure, will dissipate with adequate (room size) ventilation.

Heat Curing - For maximum physical properties and higher heat resistance, TASK™ 8 should be heat cured according to the following cure schedule:

| Temperature | Duration |

| Room Temp. (72°F / 23°C) | 1 hour |

| 150°F / 65°C | 2 hours |

| 212°F / 100°C | 2 hours |

| 265°F / 130°C | 2 hours |

Performance - Cured plastic is rigid and durable. It resists moisture, moderate heat, solvents, dilute acids and can be sanded, machined; primed/painted or bonded to other surfaces (any release agent must be removed). If sanding or machining, wear dust mask or other apparatus to prevent inhalation of residual particles. Plastic can be displayed outdoors after priming and painting. Unpainted castings will yellow when exposed to ultra-violet light.