UVO®

特征

UVO®颜色高浓缩,优异分散性,颜色一致性。非常小的添加比例可着色较多的液体环氧树脂或聚氨酯。添加的比例越多,颜色效果显著。推荐的添加范围是系统总重量的0.01%至3%。不要过度添加可能出现抑制固化/渗出。

用户决定添加量:如果是第一次在环氧树脂或聚氨酯体系中添加颜料,可能需要向少量材料中添加几滴颜色并观察结果来测试颜色效果。可能需要几个测试浇注件才能达到所需的颜色效果。

重要:结果可能因环氧树脂或聚氨酯产品的抗紫外线性而异。

说明

By Weight Using A Gram Scale: Add UVO®colorant at a ratio of between 0.01% - 3% of the total weight (Parts A + B mixed) of the material being cast. Concentrations above 1% yield a solid opaque color. Adding more than 3% by weight may cause cure inhibition.

By Volume Measured In Drops: Add 10 drops of UVO® per 3 oz (88 ml) of mixed material. If using a translucent material (like Smooth-Cast® 325 or EpoxAcast® 690) you can use 1 drop to maintain translucency of the material.

Directions For Use: Store and use at or near 73°F / 23°C. Wear vinyl gloves to prevent skin contact. After dispensing the required amount of material Parts A and B into measuring containers, add colorant to Part B and mix thoroughly. Combine Parts A and B into a mixing container and mix as directed by the product technical bulletin.

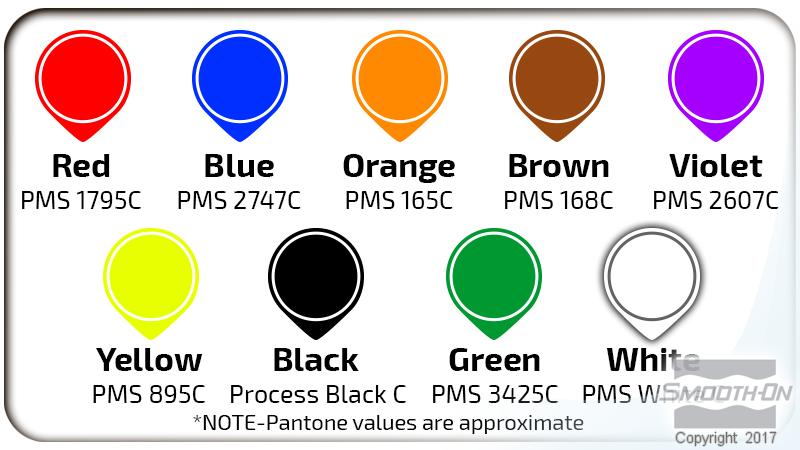

Blending Colors: Combine different colors on a palette to create a custom color before adding to material as directed above. Smooth-On offers this color guide as a general reference only and assumes no responsibility for color accuracy or matching. Results will vary from one material to another. The end user is solely responsible for determining color suitability and accuracy. Small scale testing is recommended.

The Pantone Color Matching System is most commonly used in the printing industry to communicate color. As it relates to Smooth-On color tints and pigments, the represented color is an approximation and people’s interpretation of these colors may vary. The user will determine suitability of a color or combination of colors for the rubber, resin, foam or other product used specifically for their application. Due to the variability in products that are being colored, application, color concentration and other factors, Smooth-On makes no warranty with regards to the color.