Jeff describes the project:

"This project was one that I have wanted to do since I first got into Sculpting. I am a huge fan of GI JOE® and have never seen a mask of Destro that did the character justice, or one that was just cool to look at. I finally got around to it as a personal project. I did a lot of preliminary design work to get the look that I wanted, did several sketches and research of all the looks of the character. I finally decided on a design and started sculpting. I did my research online about materials, then talked to the guys at the Los Angeles Smooth-On distributor - Reynolds Advanced Materials, and got the products they recommended.

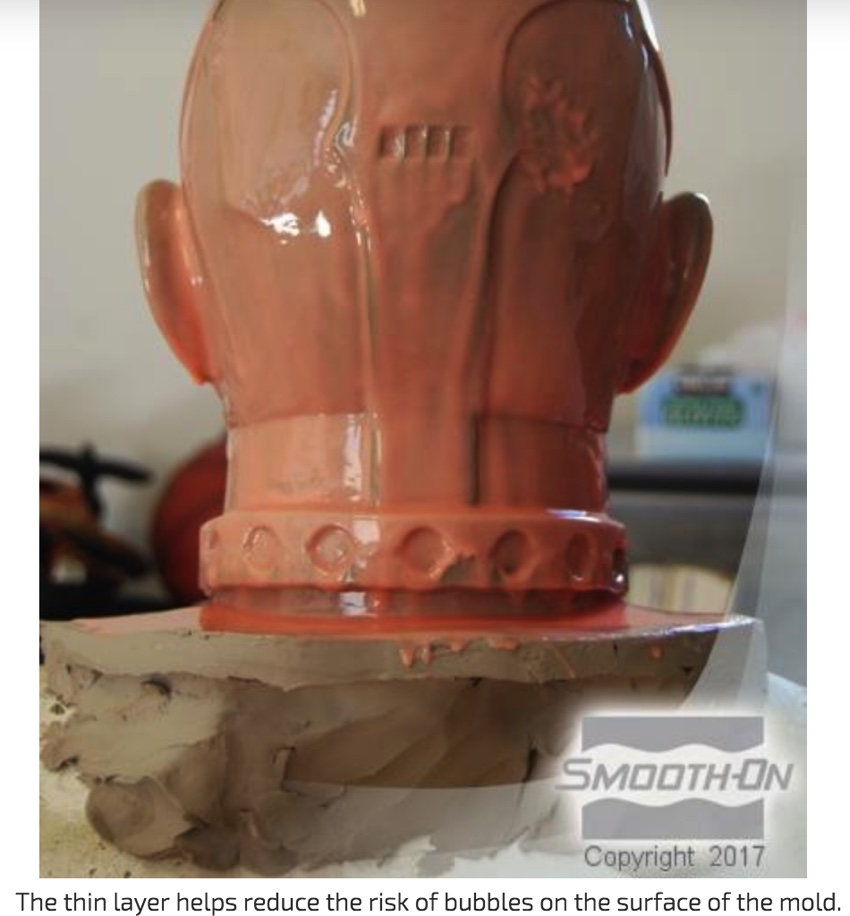

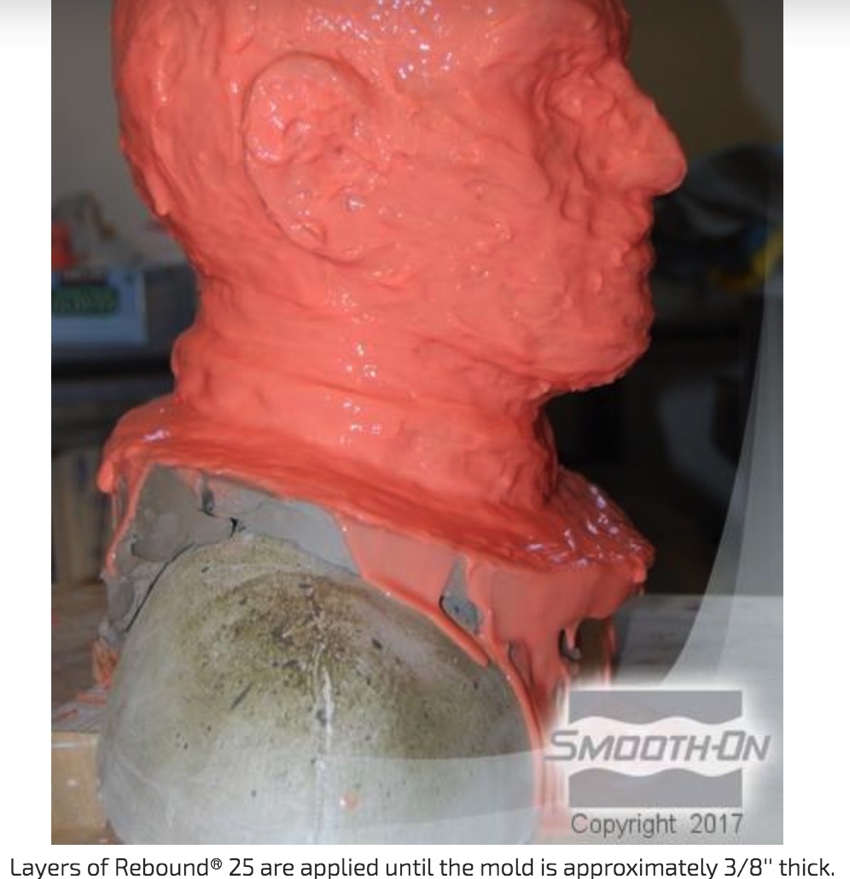

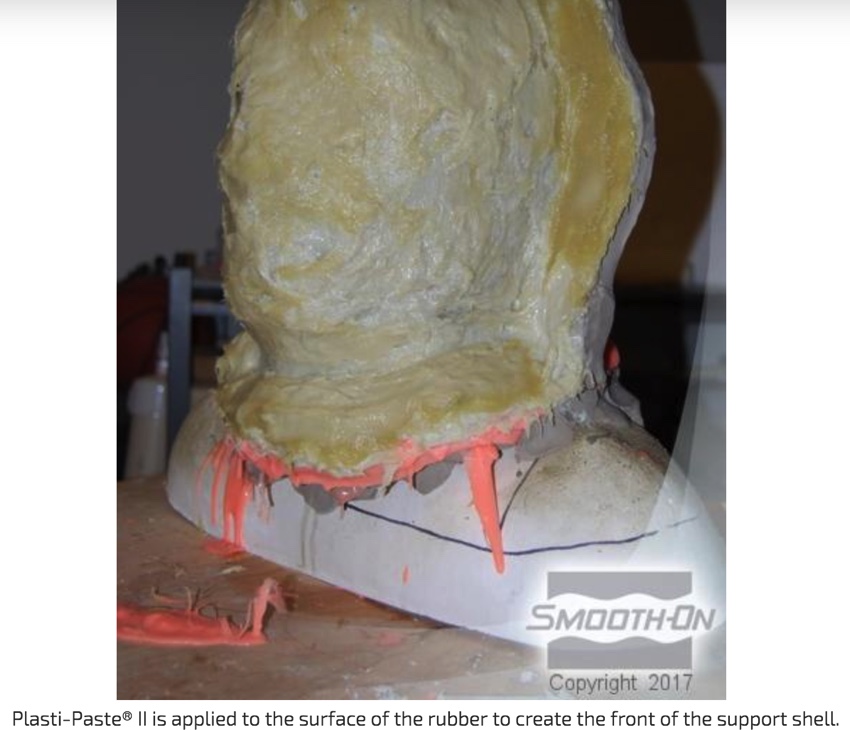

The Smooth-On products made the molding process extremely easy. I started with a sculpt in Chavant non-sulfur clay. Smoothing the clay took a lot of work but the result in the mold made it well worth it. I molded the sculpt in Rebound™ 25 because I wanted to do a one piece glove mold that I could pull off in one piece and all the seams would match up perfectly. The nice thing about the Rebound™ 25 is that it made it easy to pull and stretch it to get the mold off of the head. I backed the Rebound™ 25with Plasti-Paste® II, as a 2 part keyed shell. I had never used either of these products and they came out perfect the first time.

After the molding process I laid the 2 halves of the mask up in fiberglass cloth and polyester resin, trimmed and seamed them so that they fit over each other. Then I dry sanded the parts patched them then wet sanded them. I primed and painted them using the Alclad® II chrome paint system. It came out great. Thanks for making this possible."

The following images, provided by Jeff, outline his sculpting, moldmaking and casting process.